A NEW STANDARD IN CIRCULAR ECONOMY

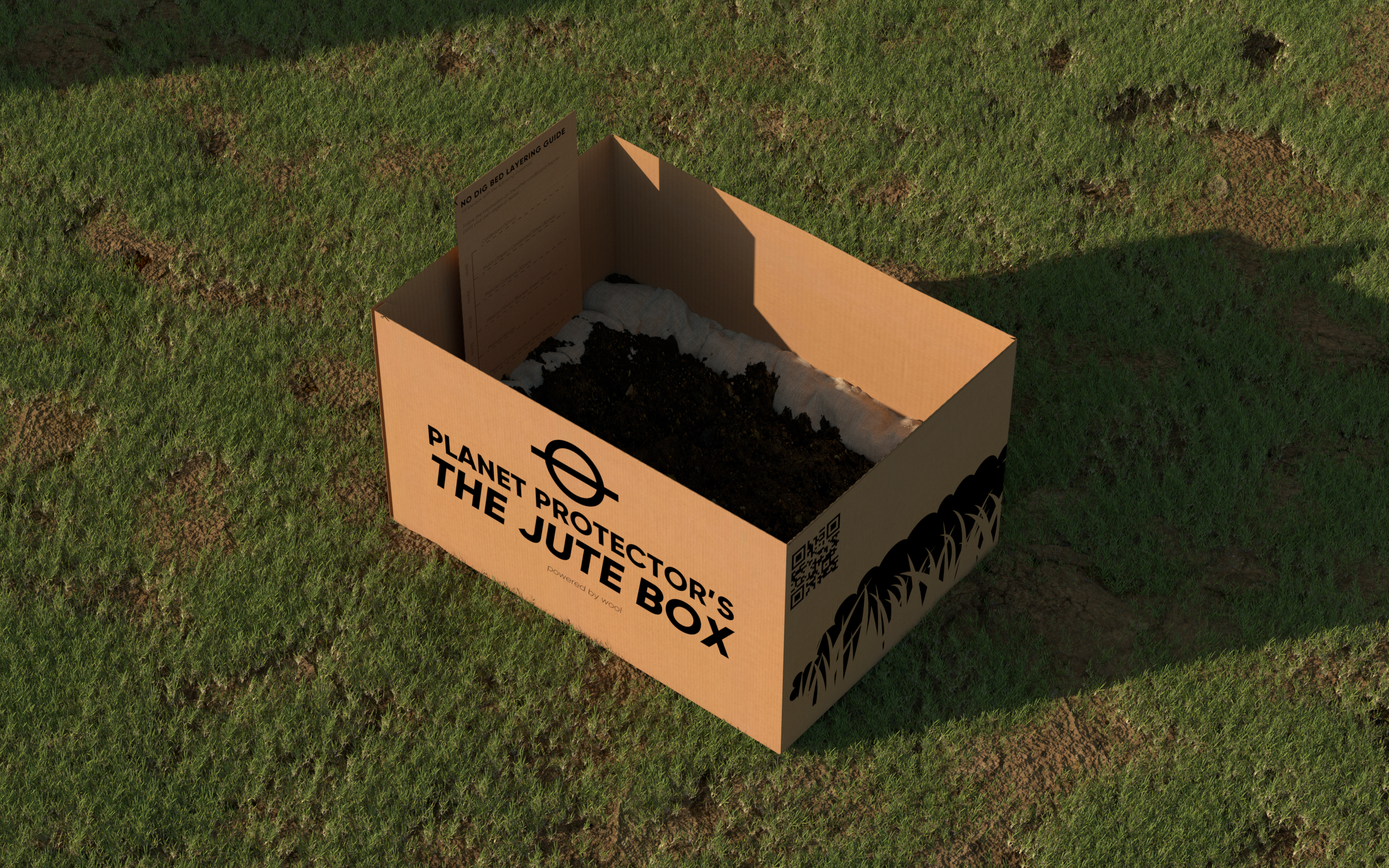

JUTEBOX

Year//

2019

Team//

Andrew Taylor, Timothy Lim, Jacob Ho and Epifanio Pereira

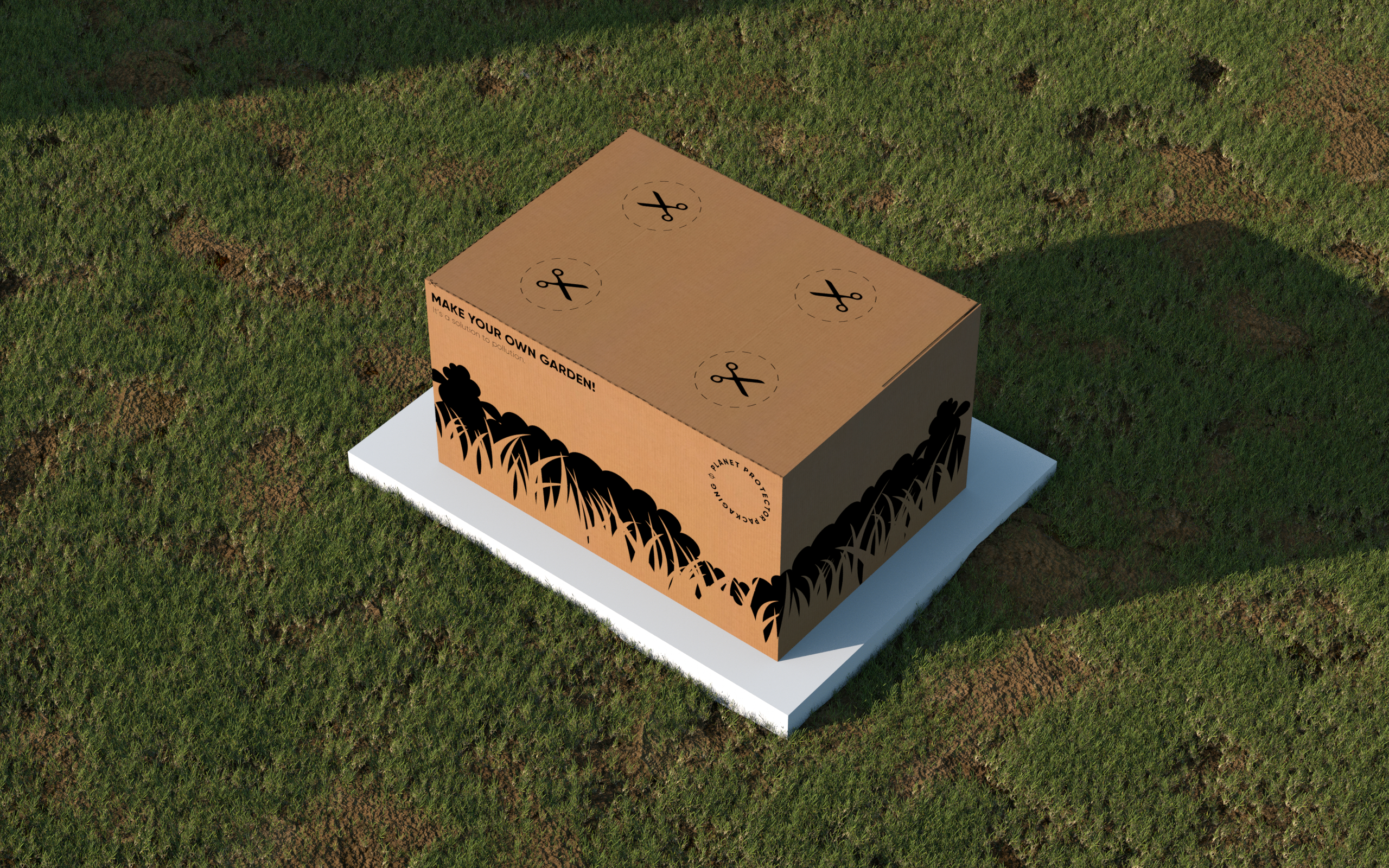

The Jute-box packaging and cooling solution for food delivery introduces a new standard in circular economy while building upon the values of our client - Planet Protector.

PROBLEM STATEMENT

A WICKED PROBLEM

We were tasked with educating users on sustainable practices while simplifying the assembly and disassembly of planet protectors cardboard packaging. The design needed to optimize and implement a new end of life process for the company's organic-based box liner - Woolcool. The redesign of Planet Protector’s insulative packaging must also extend to the companies corporate identity and marketing material.

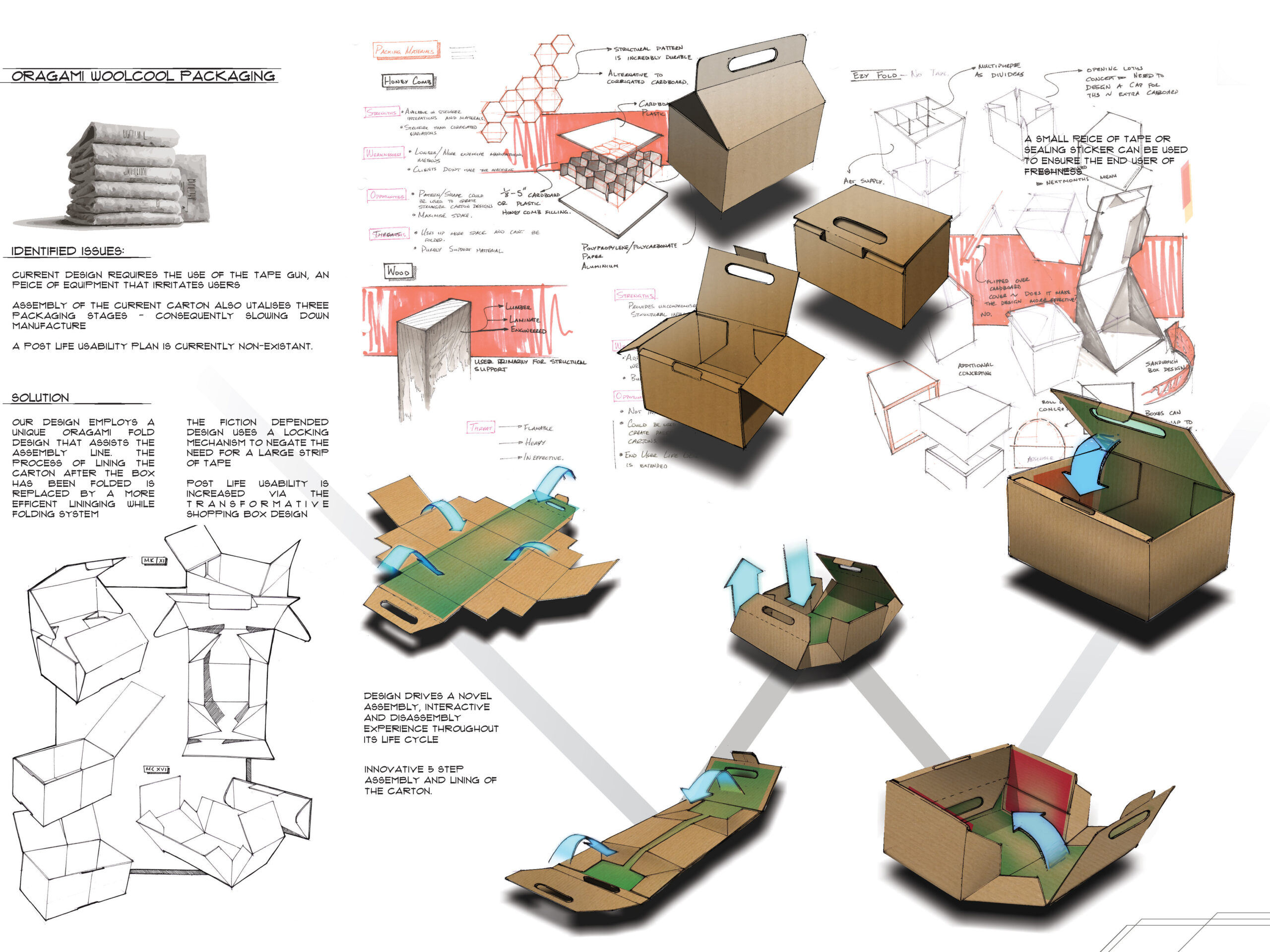

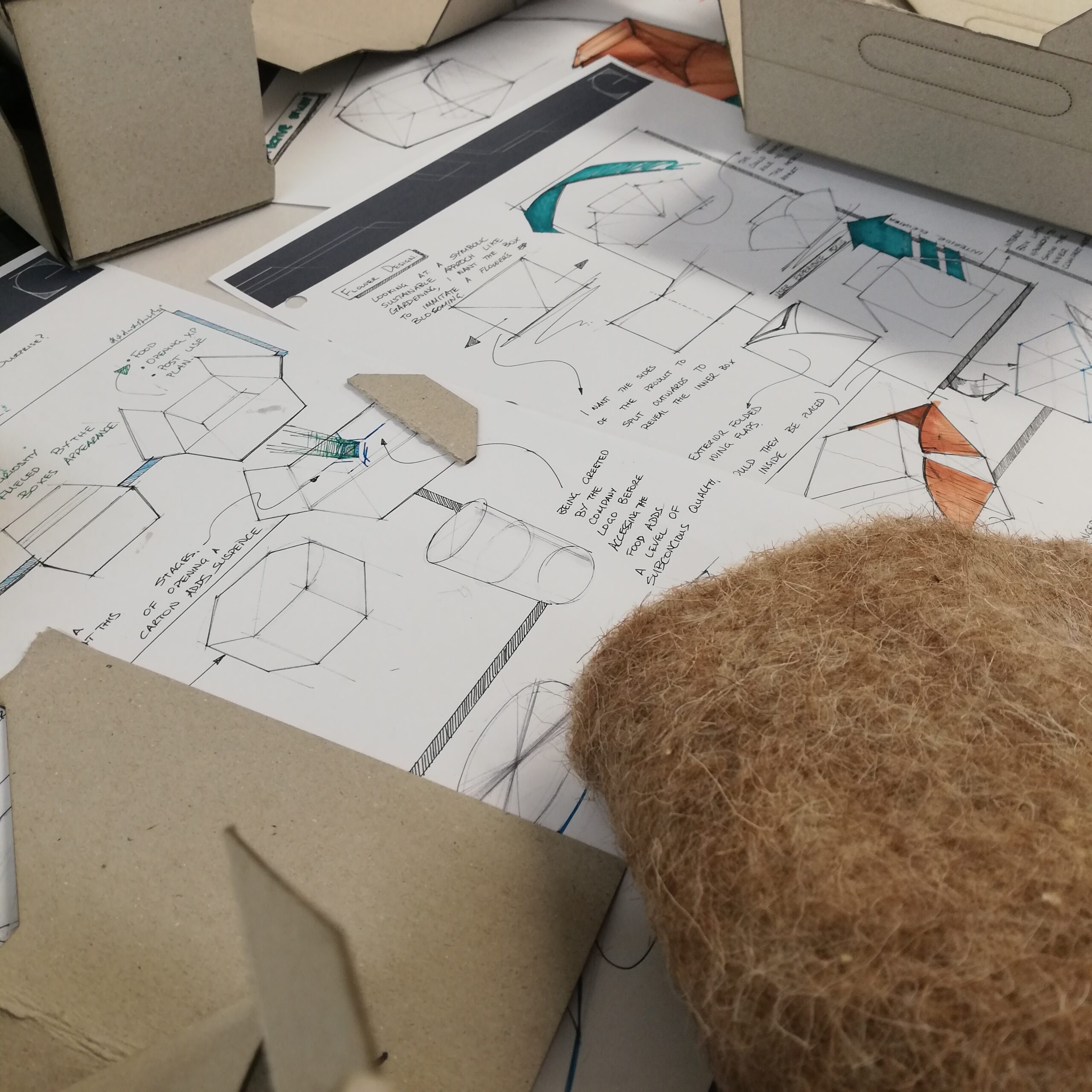

RAPID ITERATION

EARLY DEVELOPMENT

During our concept phase, we explored numerous carton concepts that incorporated the woollen liner within the folding phase of the box manufacture. Dubbed the Oragami packaging, our initial intention was to lower the manufacturing time for local food distributors as they assemble the boxes. A variety of boxes were developed in parallel with a renewed design identity focusing on biodegradability and cyclic design of the packaging.

OBSERVED ISSUES

REFINED AIM

"It is the aim of Planet Protector to both create products that can be diverted from landfill and to educate the client and end-user on how to reach this desired outcome.” This became the core focus of our product as we moved into branding and prototyping. In specific, we noted the use of HDPE in the planet-protectors cooling liner to be a material that prevented a seamless biodegradable solution.

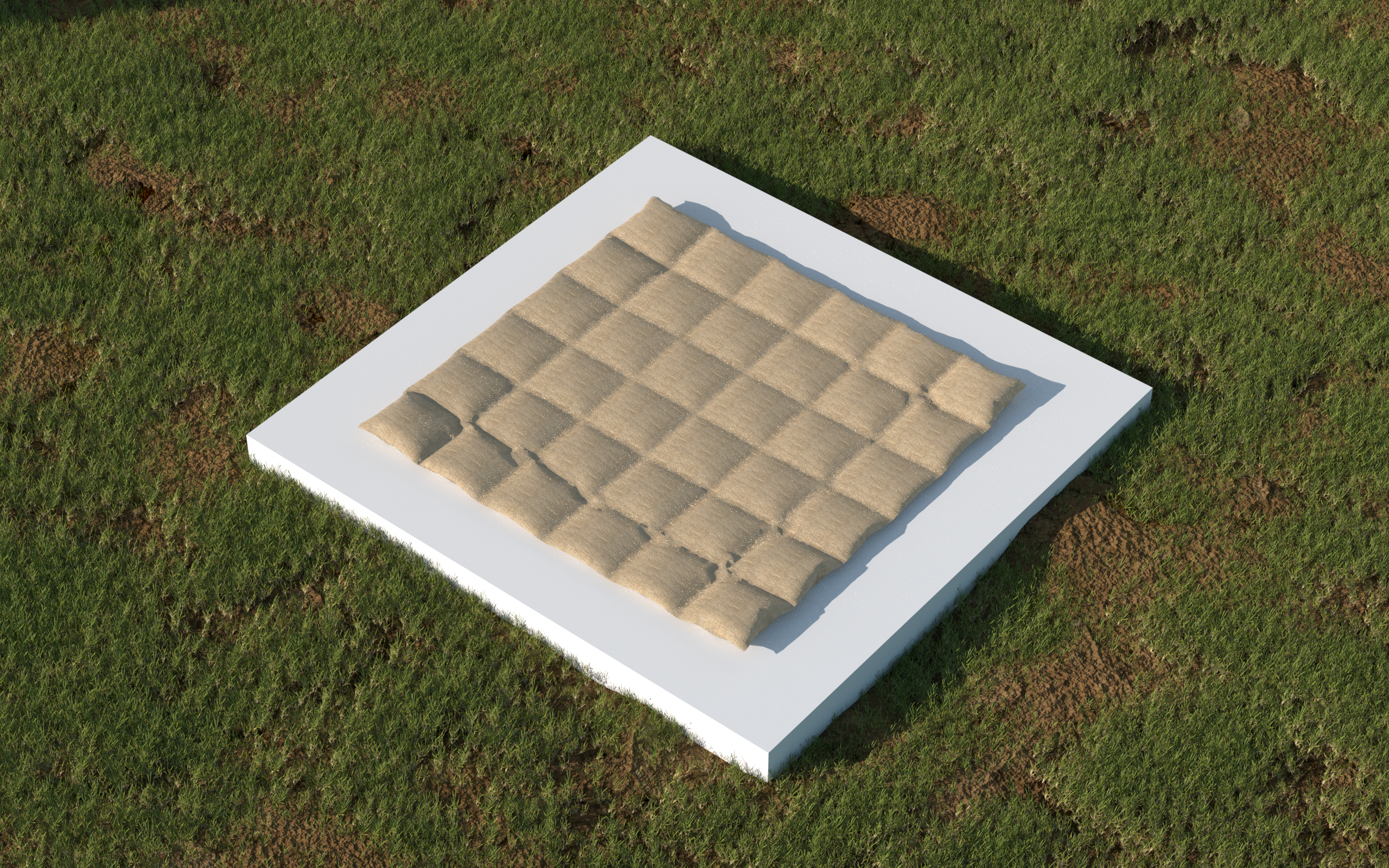

THE JUTE IN JUTEBOX

THE NEW INSULATOR

Manufactured from jute, an organic vegetable fibre, the material is known for its excellent biodegradability, strength and sustainability. It has a course rustic texture and is commonly used in the garden, as mats for pets and in the Arts and crafts industry. Our product employs the materials' excellent biodegradability and insulative properties by combining knops and biodegradable cotton weaving. Knops are then sandwiched between the hessian layers and quilted into position by a multi-head sewing machine. This unique combination of these two materials allows knops to optimise airflow and moisture absorption while increasing packaging speeds due to the lack of folding required when prepping a meal box.

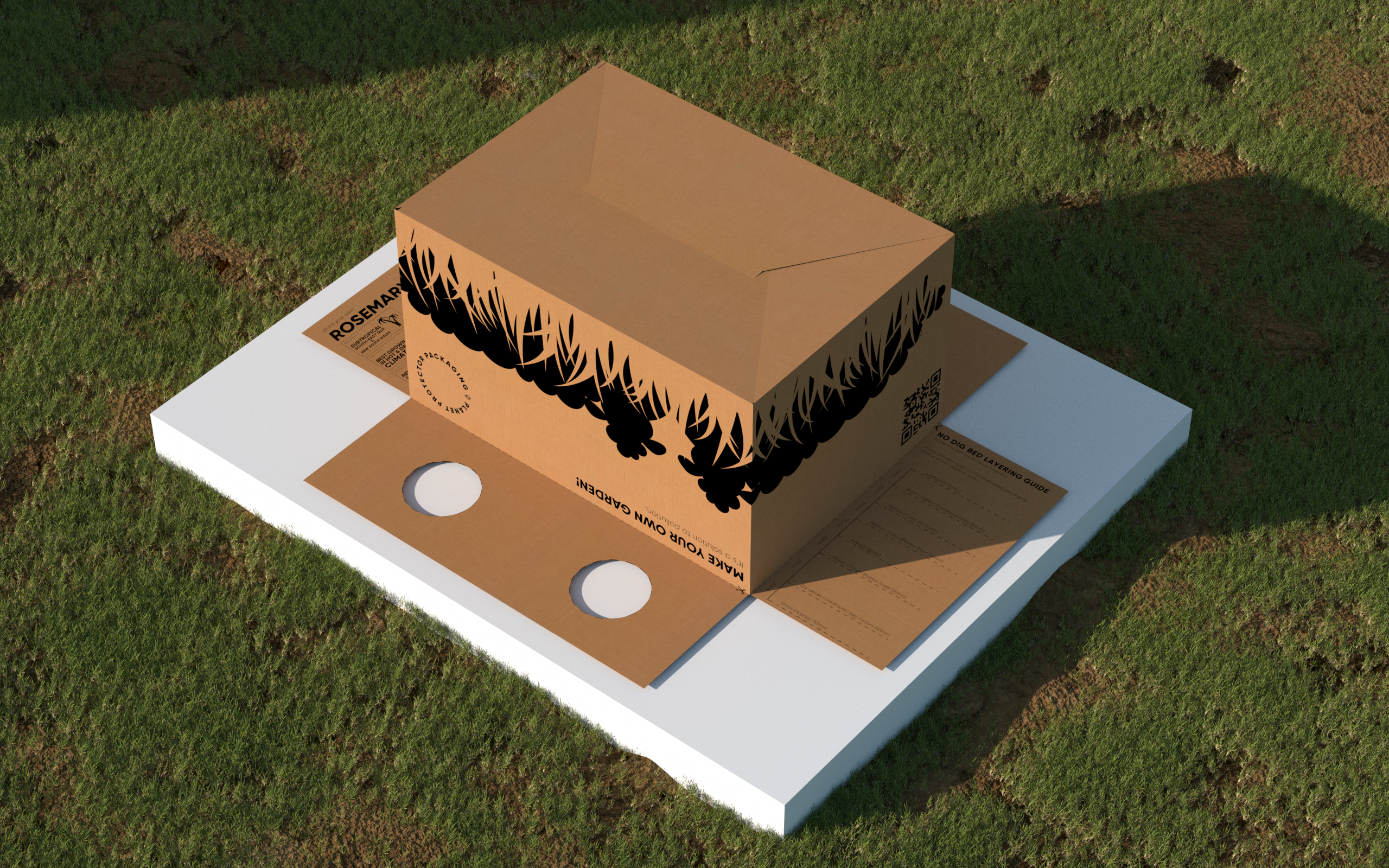

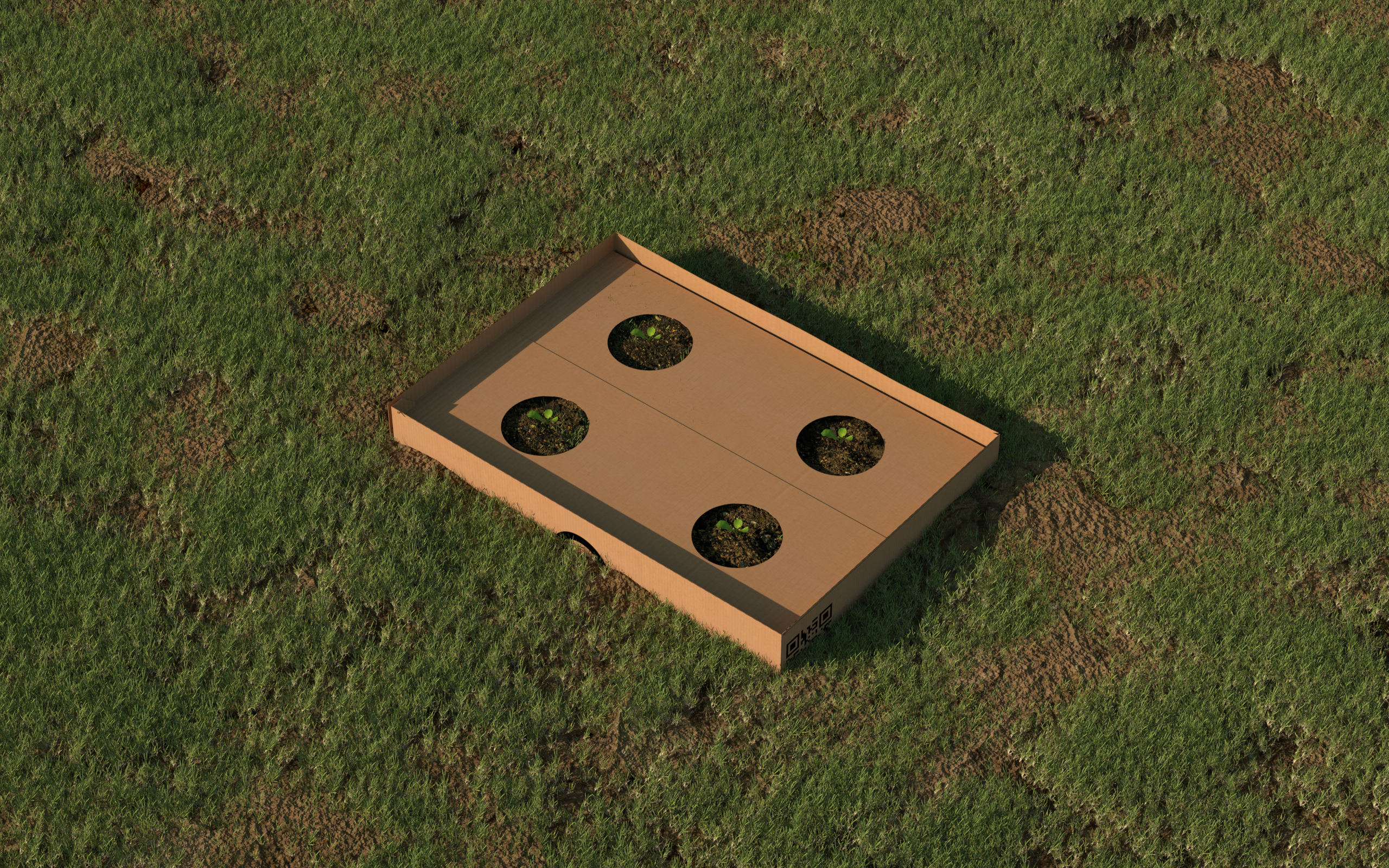

THE LAYERING CONCEPT

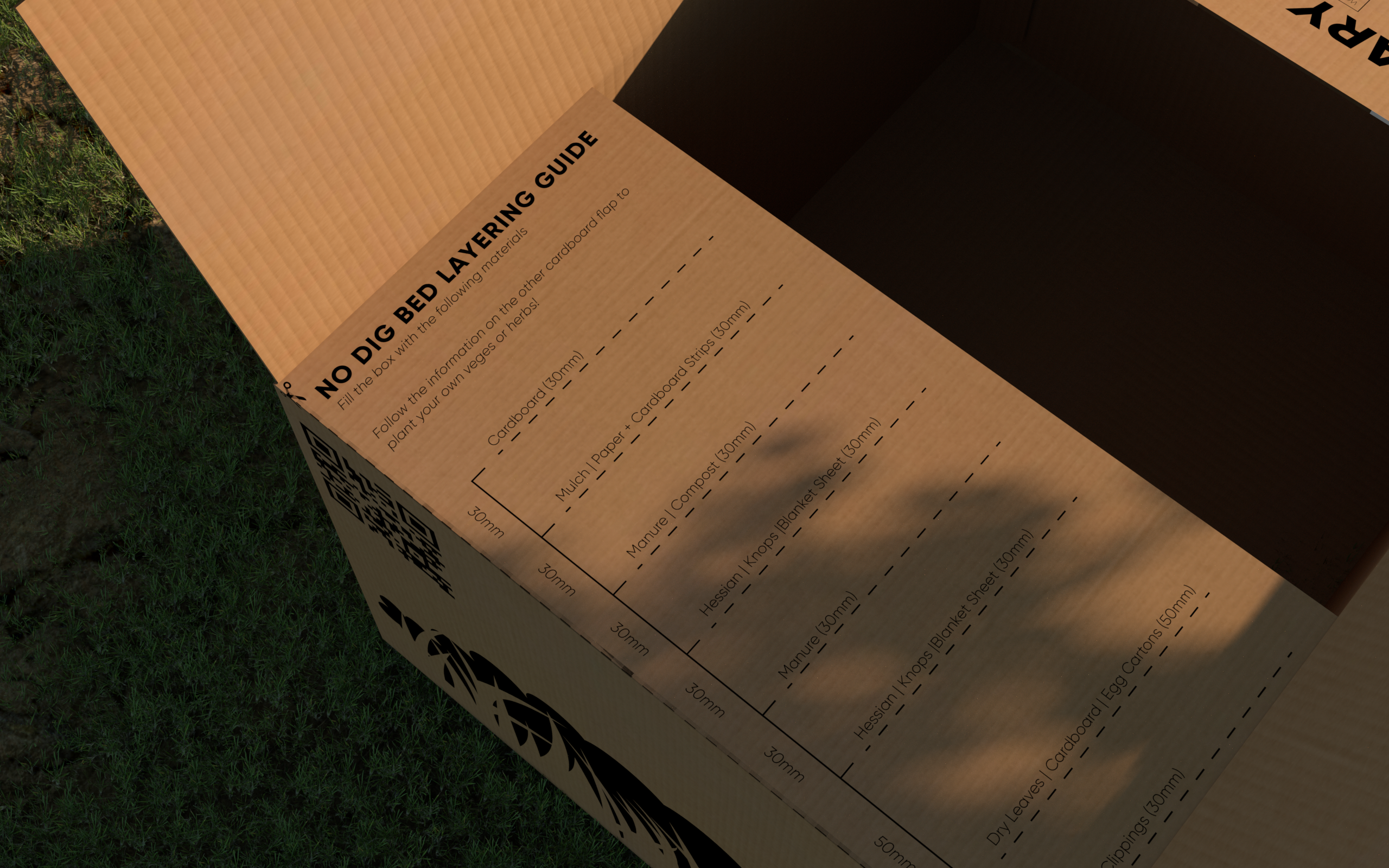

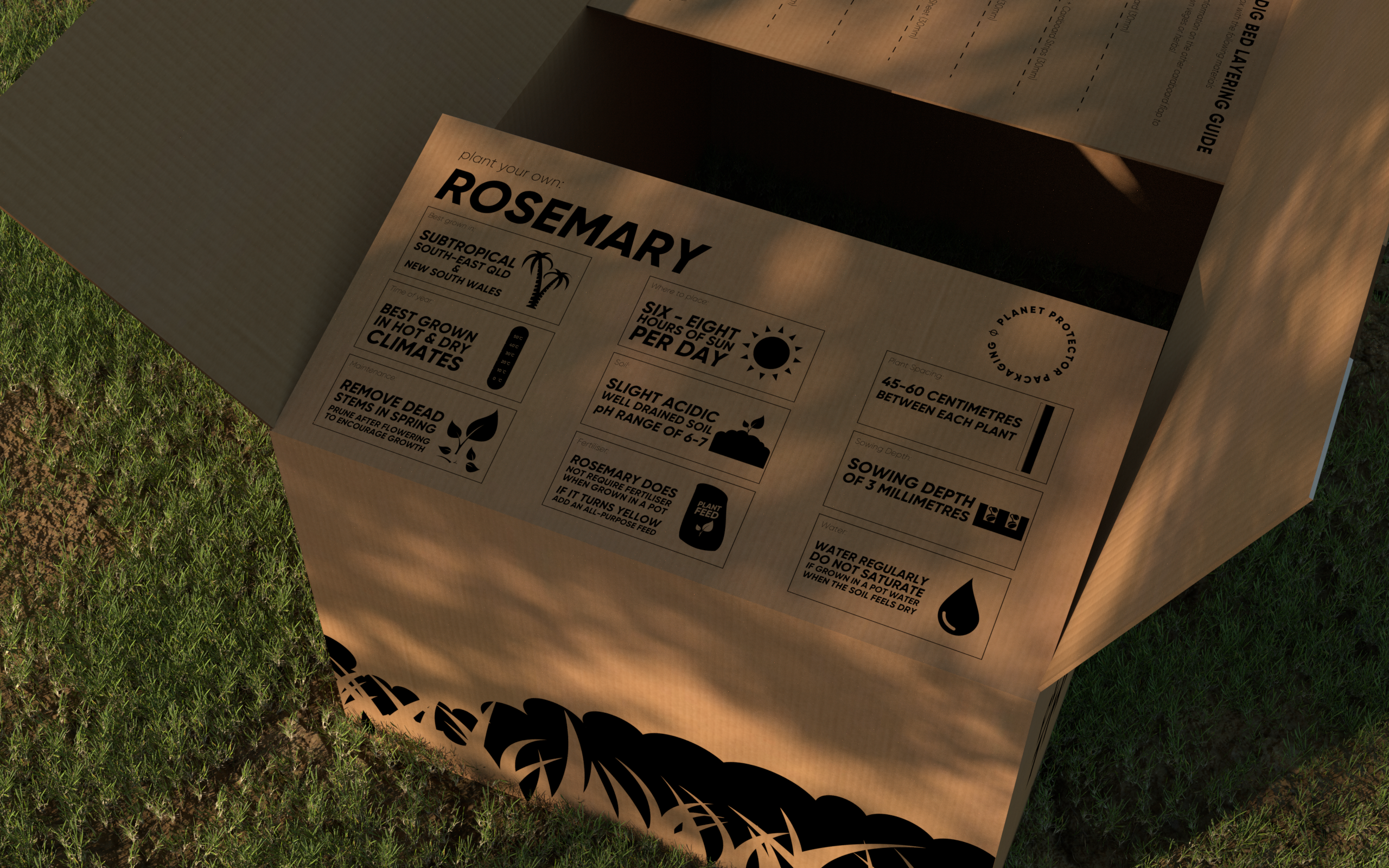

NO DIG GARDENING

The removal of HDPE allows the packaging insulation to be fully biodegradable and compostable. Hessian supported our proposal due to its organic nature. When combined with the naturally sourced knops, the two materials served as an excellent source of nutrients for growing plants. Rich in nitrogen and carbon, the wool and hessian can be cold composted to create a layer of nutrients essential for plant and worm growth. When layered in a garden bed, they also allow for airflow and retains moisture between watering periods. The set-up process for Jute-box is described below.

USER EDUCATION + CONNECTIVITY

JUTEBOX

The addition of the no-dig gardening method into the design of the packaging also serves as a way for Planet Protector to become a positive influence outside of just the Jute Box. The no-dig gardening method uses common household waste materials from around the home such as paper, cardboard, food scraps, and garden waste. Therefore the Jute Box also serves to provide users with a natural way of disposing of these materials by themselves without burdening any external waste management systems.

THE PERFECT SOIL BED

JUTE-BOX GARDEN

Following the printed layering structure described on the Jutebox's flaps, the user can mix and match food scraps depending on what is available. The manure can be substituted for compost if the user has it on hand either bought from a store or produced themselves from food scraps while the box's biodegradable surface allows the product to be placed on grass, starving the foliage underneath of light and creating a suitable surface for the garden bed to integrate into the soil.